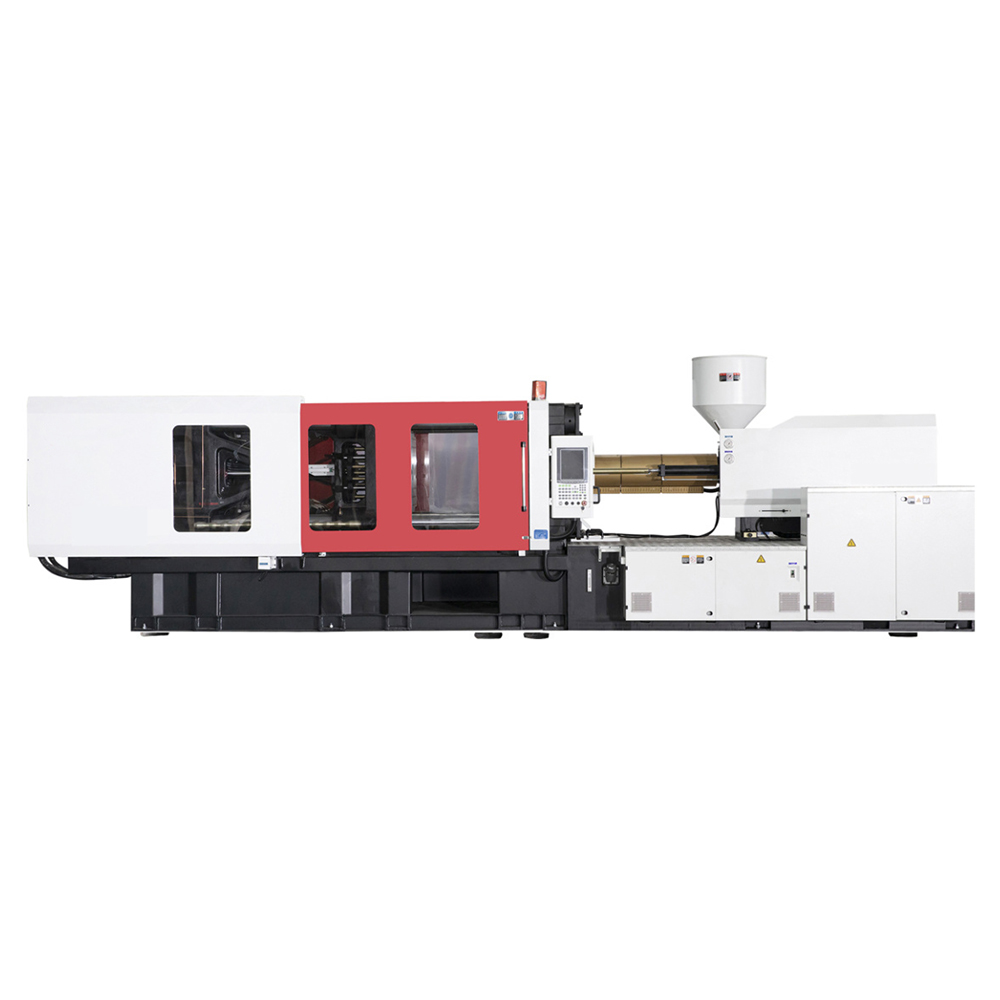

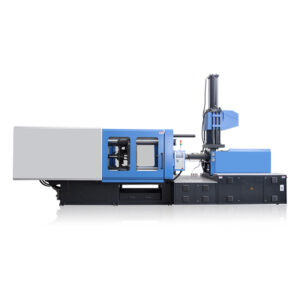

High speed injection molding machine

High speed precision injection molding machine

Description

High speed injection molding machine is specialized for thin-wall products like: plastic food container, cup, spoon, fork and so on.

|

|

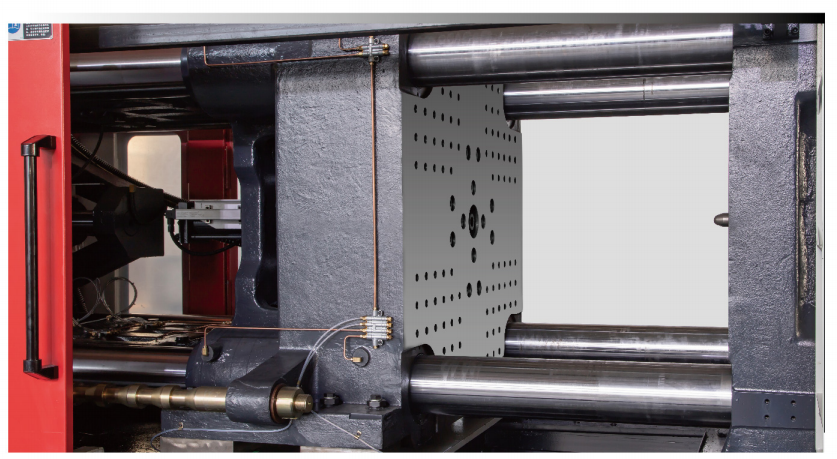

| Improved platen with high rigidity structure. Especially suit to thin- wall products.

Self-lubrication bushes ensure high-speed performance. Nitride link with optimized structure and more robustness and stability. Equipped with lly metallici tie bar with enhance strength to lengthen the lifespan. |

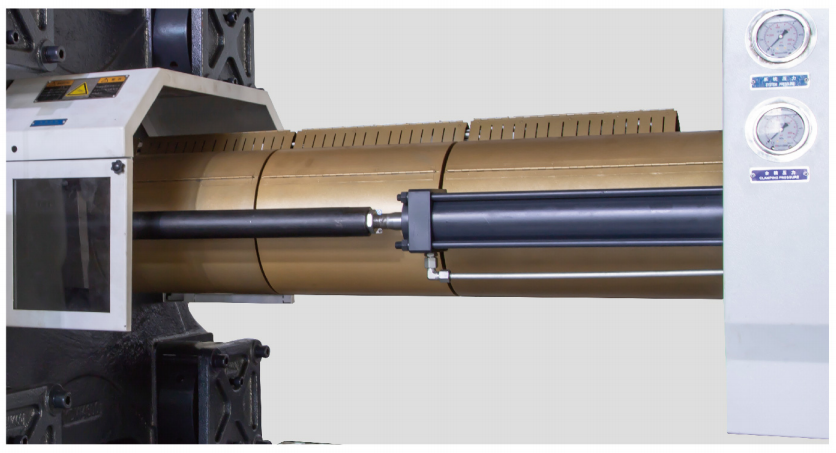

Pid Temperature Control Have,precise Temperature Of Barrel.

There Are Several Screws And Barrels With Optimal design, respectively,nitrite Chromium Plating,dual-metal,which Is suitable For Different Plastic Material’s Request. Two-guided Direct Line Guided Bar Supports,single-balanced Rapid Injection. The High-torque Hydraulic Motors Offer A Stable Plasticizing Capacity, high-precision Linear Transducer Device Position Detection Enable Accurate Measurement. Multi-injection Speed And Pressure And Multistage Pressure Setting,switch from The Injection Time,location, pressure Control To Ensure The Quality Of Molding. Multistage Back-pressure And Pre-injection Speed Computer-controlled,screw With The Features Of Pre-injection Ant-flow And Clean material Automatic Prevent Cold Material Starting Function To Ensure That The Screw,barrel Will not To Be Damaged. |

|

|

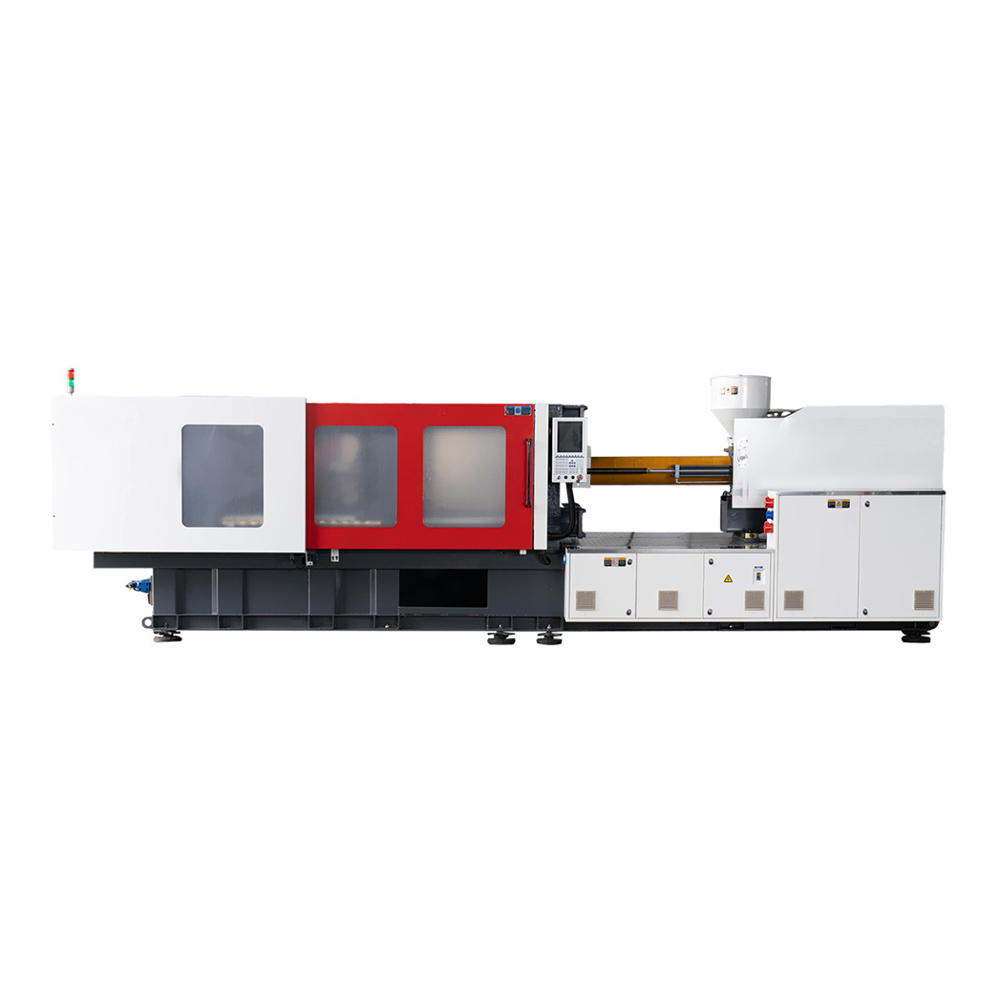

| The manual plug valve hydraulic system make the machine having quick and smooth motion response

Pressure and flow double proportional valve control High-performance imported hydraulic unit with optimiing allocation The oil tank has a big opening hole so can be cleaned easily Setting with buffer and differential device for clamping unit to guarantee quick and smooth performance of mold open and close. All pipelines shall be designed without welding, so as to avoid hydraulic leakage and welding slag falling into the hydraulic line and damaging hydraulic components. All hydraulic cylinders are sealed with four layers, from the outside to the inside: DHS dust proof ring, ST shaft sealing ring, wear-resistant guide belt, UHS sealing ring, |

Special PLC computer controller for plastic injection machine use,control and display relatively independent with high reliability Technical parameters pre-setting and storage function

Parameters information protection function Charging barrel temperature deviation automatic adjustment function Abnormal alarm function Front and back door emergency stop button Timely monitoring can display the condition of each motion Electrical motor safety protection device Robotic pincher interface Material feeding photoelectric switch System hardware I/Q detection function Charging barrel temperature is controlled accurately bycomputer setting and PID closed-loop manner Screen protection function,prolong the life of screen using |

| Specification | UNIT | BF368h | BF460h | ||

| INJECTION UNIT | A | B | A | B | |

| Screw Diameter | mm | 52 | 55 | 55 | 60 |

| Screw L/D Ratio | L/D | 27.5 | 26 | 28 | 25.8 |

| Shot Volume | cm³ | 530 | 593 | 594 | 707 |

| Injection Weight | g | 483 | 541 | 541 | 643 |

| Injection Speed | mm/s | 420 | 420 | 461 | 461 |

| Injection Rate | g/s | 811 | 908 | 997 | 1186 |

| Injection Pressure | Mpa | 171 | 153 | 171 | 144 |

| Max. Screw Speed | Rpm | 0-350 | 0-350 | 0-350 | 0-350 |

| CLAMPING UNIT | |||||

| Clamping Force | Kn | 3680 | 4600 | ||

| Toggle Stroke | mm | 605 | 605 | ||

| Tie Bars Distance | mm | 635*615 | 680*680 | ||

| Max. Mould Height | mm | 670 | 680 | ||

| Min. Mould Height | mm | 250 | 270 | ||

| Eject Stroke | mm | 100 | 100 | ||

| Eject Tonnage | Kn | 80 | 80 | ||

| OTHERS | |||||

| System Pressure | Mpa | 16 | 16 | ||

| Motor Power | Kw | 55+37 | 55+55 | ||

| Heating Power | Kw | 28.5 | 33 | ||

| Machine Dimensions | m | 7.25*1.95*2.2 | 7.1*1.9*2.2 | ||

| Machine Weight | Ton | 14.5 | 18.5 | ||

| We reserve the right to make changes of machine specifications and photos without notice due to continuous improvement. | |||||

Reviews

There are no reviews yet.