Plastic Injection Molding Machine 230 ton 270 ton 300 ton

Plastic injection molding machine clamping force 230 ton 270 ton and 300 ton with servo system

Description

MAIN FEATURES (Detail is the Key of Success):

|

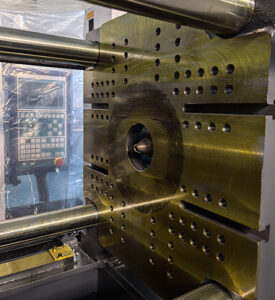

1. All models platen are with T slot Our machine has T-slot platen design, easy for fixing mould more time and reducing the screw hole damage. It is also good to extend the platen life. Meanwhile, the plate has enough thickness to ensure the mould to be closed tightly, it will improve the product shaping quality and extend the mould life. |

|

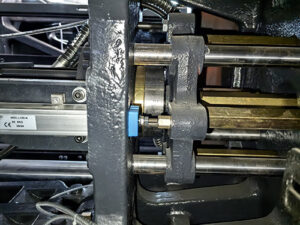

2. Integrated toggle system Front link toggle adopts integrated design to improve the toggle system strength and also whole clamping system rigidity and accuracy. |

|

3. Double cylinder carriage moving function Adopt two parallel hydraulic cylinders to move the carriage. It ensures the nozzle touching to mould more tightly. The screw and barrel will not be deformed and the life will be extended. Double-layer barrel cover to prevent workers from getting burned during operation |

|

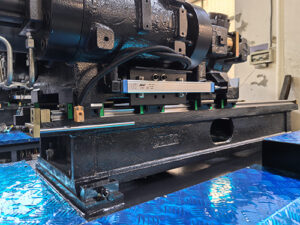

4. Adopt linear slider for injection unit Adopt linear slider instead of guider bar, reduce friction force during injection and charging material, more efficiency and balance. |

|

5. Electronic back pressure valve The electronic back pressure valve can control the back pressure by controlling the voltage, so that the plastic can be fully mixed during the injection molding process, thus ensuring the consistency of the product. |

|

6. Auto mould thickness adjustment function and auto screw rotary speed inspection All machine equipped with auto mould thickness adjustment function and auto screw speed inspection function, easy for customer adjust mould thickness and charging setting . |

|

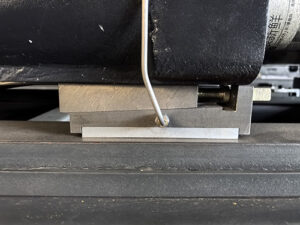

7. Copper + graphite moving plate support foot Use copper + graphite foot for supporting moving platen, less weight, easy for assembly and maintenance, less abrasion, longer working life |

|

8. Hydraulic pipe fast joint without welding New serial machines adopt fast joint connection for hydraulic steel pipe, non welding connection will reduce the oil leakage and also look more beautiful |

|

9. Main ejector quick release device |

|

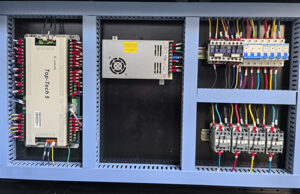

10. Advanced controller system Adopt Haitian, EST, Techmation or KEBA brand special injection machine computer, international famous brand and quality, easy operation and control, multi-languages for choice. |

|

11. Advanced servo motor and gear pump for energy saving. |

|

12. Advanced Servo Controller |

MACHINE SPECIFICATIONS:

| Item Name | Unit | BF230e | BF270e | BF300e | ||||||

| INJECTION UNIT | A | B | C | A | B | C | A | B | C | |

| Screw Diameter | mm | 40 | 50 | 55 | 55 | 60 | 65 | 60 | 65 | 70 |

| Screw L/D Ratio | L/D | 22 | 20 | 18.5 | 23 | 21 | 19 | 23 | 21 | 19 |

| Shot Size(Theoretical) | cm³ | 342 | 456 | 551 | 677 | 805 | 945 | 805 | 965 | 1080 |

| Injection Weight(PS) | g | 311 | 415 | 502 | 615 | 732 | 860 | 732 | 860 | 985 |

| Injection Rate | g/s | 103 | 128 | 155 | 128 | 155 | 184 | 224 | 266 | 312 |

| Injection Pressure | Mpa | 207 | 177 | 143 | 200 | 168 | 143 | 200 | 168 | 143 |

| Screw Speed | Rpm | 180 | 180 | 175 | ||||||

| CLAMPING UNIT | ||||||||||

| Clamping Force | Kn | 2300 | 2700 | 3000 | ||||||

| Toggle Stroke | mm | 475 | 550 | 590 | ||||||

| Tie Bars Distance | mm | 520*520 | 580*580 | 615*615 | ||||||

| Max. Mould Height | mm | 540 | 580 | 630 | ||||||

| Min. Mould Height | mm | 200 | 200 | 200 | ||||||

| Eject Stroke | mm | 140 | 150 | 150 | ||||||

| Eject Tonnage | Kn | 65 | 65 | 70 | ||||||

| Eject Number | P | 5 | 13 | 13 | ||||||

| OTHERS | ||||||||||

| Max. Pump Pressure | Mpa | 16 | 16 | 16 | ||||||

| Pump Motor Power | Kw | 30 | 37 | 37 | ||||||

| Heating Power | Kw | 11.5 | 13.5 | 18.5 | ||||||

| Machine Dimensions | mm | 5.85*1.5*2.3 | 6*1.58*2.3 | 6.3*1.66*2.35 | ||||||

| Machine Weight | Ton | 7 | 8.5 | 9 | ||||||

| Oil Tank Capacity | L | 340 | 470 | 590 | ||||||

| We reserve the right to make changes of machine specifications and photos without notice due to continuous improvement. | ||||||||||

Reviews

There are no reviews yet.